Coating

As part of our platform of precision glass manufacturing services at China Glass Quartz Parts Inc., we offer a variety of glass coating options. We leverage many different materials and a variety of technologies to provide solutions for a multitude of end-use applications. Our engineering and production staff works closely with customers to deliver solutions that offer superior protection and enhance the reliability and service performance of glass products. We are up to date with all the latest technological advancements in the coatings field and develop optimized coating solutions based on the operating environment and production requirements.

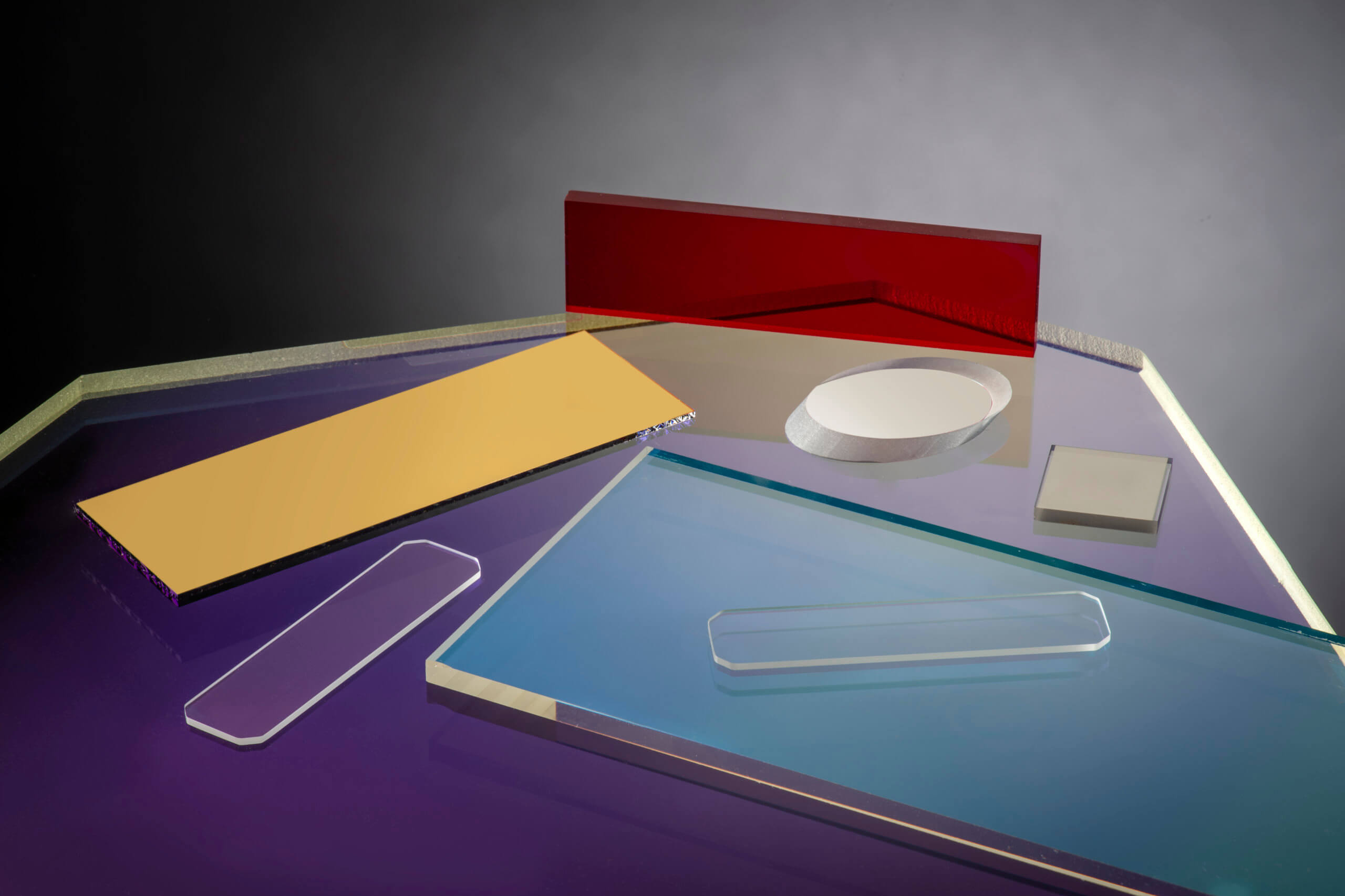

We leverage dip-coating techniques as well as sputter deposition and vacuum deposition to apply coatings to the glass substrate, and all of our processes can be fine-tuned to obtain specific properties in the coated films. Options include reflective and anti-reflective coatings as well as conductive and resistive types. We offer shortwave pass filter coatings and can create variations, for example, to block specific wavelengths while enhancing others to develop custom glass filters. Our computer-controlled vacuum, dipping, and sputtering chambers offer high-stability performance and accommodate products ranging from 0.1” to 24.0” in diameter and .004” to 12.0” in thickness.

Along with high-performance borosilicate and soda-lime glass substrates, we process a variety of types and grades of fused quartz, fused silica, glass ceramics, and other materials, such as synthetic sapphire and filter glass. We operate within an ISO 9001:2015 compliant framework, and our coating systems and quality analytics conform to Mil-spec, ASTM, ANSI, and other industry standards. Whether it is a small order or volume production, we offer short lead times and competitive pricing. For more information about our glass coating technologies and our process capabilities, contact us directly.