CNC Machining

At China Glass Quartz Parts Inc., our capabilities include CNC machining to extremely tight tolerances. We combine precision CNC machining equipment and diamond tooling with sophisticated CAD/CAM programming tools to make our processes remarkably accurate and efficient. With our multi-disciplined engineering and extensive knowledge of CNC machining and all other methods of glass fabrication, we understand the challenges of creating glass products with complex shapes and intricately detailed features. Our company-wide quality assurance systems comply with ISO 9001:2015 and other industry standards.

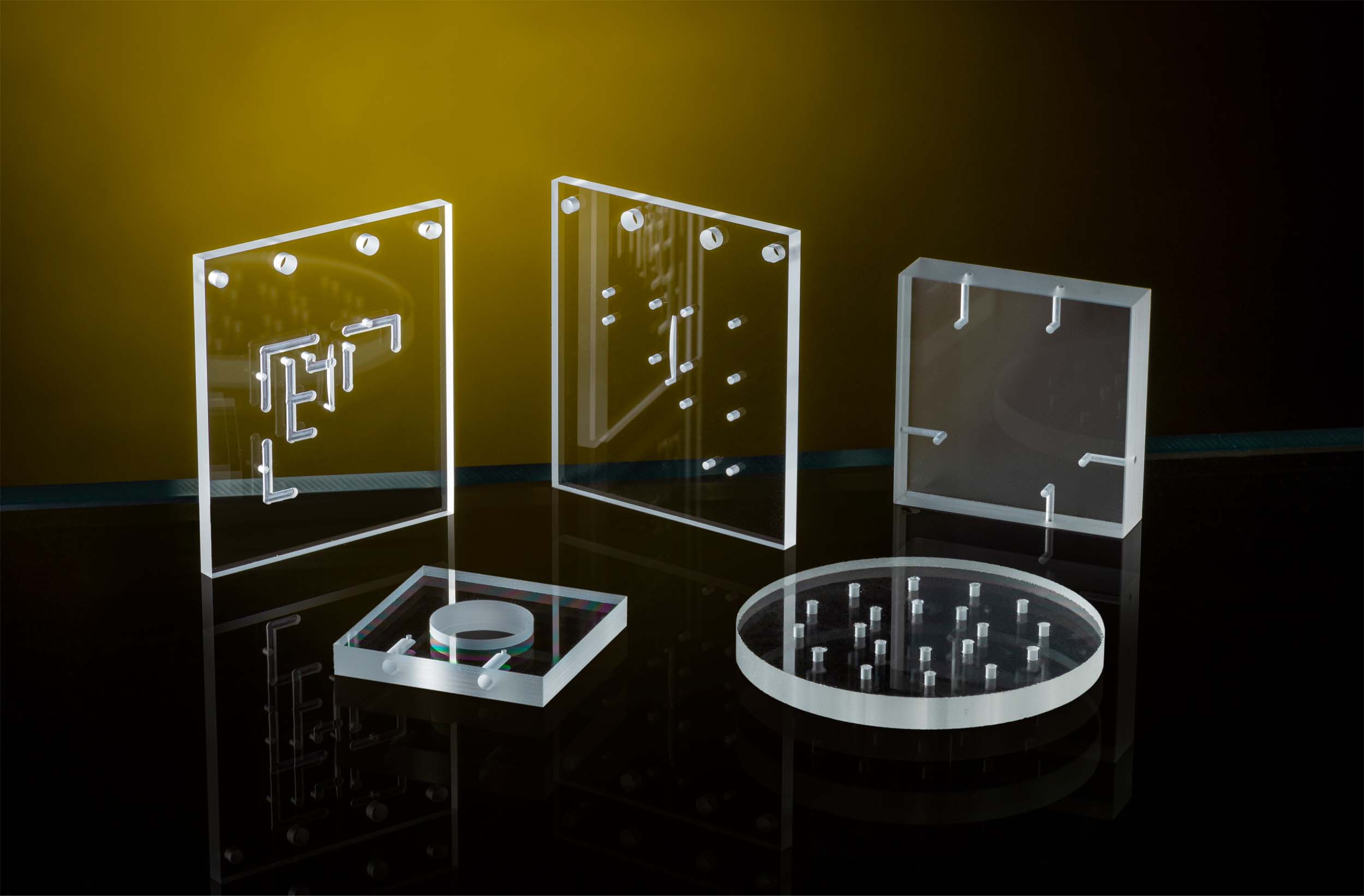

We use multi-axis milling and drilling equipment to create glass shapes with dimensions of up to 30” in length and 17” in width or diameter. Along with many different types and grades of borosilicate and soda-lime glass, we machine fused quartz, fused silica, glass ceramics, and range of other materials measuring from .004” up to 12.0” in thickness. We can drill small diameter holes down to .017” in diameter, engrave lightweight design patterns, and create ultra-precise bevels, slots, grooves, profiles, etc. Even when machining the toughest materials, we accurately and repeatably obtain micron-level tolerances.

Our machining department produces glass flats with precise perimeter accuracy and small scale to large-scale optical lenses, prisms, and light pipes. Other examples include glass and quartz wafers, cuvettes, flow cells, and specialty glass and quartz shapes for advanced, technology-driven applications across industries. Products are manufactured and tested in compliance with Mil-spec, ASTM, SEMI, DIN, and other relevant industry standards. From prototyping to high volume production, our machining processes are stable, accurate, and repeatable. To learn more about our precision CNC machining capabilities or to make an inquiry, contact us directly.